The 6-Second Trick For Bulk Materials Handling

Wiki Article

Rumored Buzz on Bulk Materials Handling

Table of ContentsBulk Materials Handling Fundamentals ExplainedThe Definitive Guide to Bulk Materials HandlingBulk Materials Handling for BeginnersExcitement About Bulk Materials Handling

There are 3 kinds of manufacturing production procedure;, and. These three production types function as adheres to: 1. Make-To-Stock (MTS) In this system a factory generates goods that are held in stock at stores as well as display rooms. This suggests that a market for the goods needs to be anticipated to make sure that the products can be produced in development ready for the customer.2. Make-To-Order (MTO) The make to order technique allows the manufacturer to wait until orders are gotten before manufacturing begins. This makes it a lot easier to manage inventories as well as respond to market need. Nevertheless, customers will certainly need to wait for their products to be produced and the maker will certainly need a stable stream of orders to maintain the manufacturing facility in manufacturing and profitable.

Make-To-Assemble (MTA) This method resembles make to stock, other than the factory will certainly generate part in anticipation of orders for setting up. This means that the producer is all set to fulfil consumer orders as they show up, but can leave the producer with a stock of unwanted components if there is no need.

In addition to increasing globalization, which has actually been essential to quick growth for several nations, an emerging discussion is which sector, services or manufacturing, can be the primary source of development for developing nations today. The East Eastern center as well as high earnings countries globalized through manufacturing-led tasks, having followed the typical development path from farming through manufacturing as well as just later to solutions.

The Greatest Guide To Bulk Materials Handling

For the Center East as well as North Africa (MENA) nations, which industry path to development, services or manufacturing, could arise as well as be fostered? For production, essential advantages consist of: the opportunity of range economic situations which drive down production expenses; the usually adverse correlation in between manufactured items rates as well as demand; and also the opportunity to export the sector's output to richer established countries, therefore increasing the output base as well as neutralizing the results of any kind of labor-saving productivity gains.Provided the value of wide globalization to a market's possibility to add to sustained long term development, an intriguing finding of the EDP is that while MENA countries drew in fairly little international straight investment (FDI) to the production industry about other industries, this FDI developed disproportionately more tasks than FDI in other sectors.

The bottom line? Nongovernment services and production can work as engines of both work production and also earnings growth in MENA. However, the court is still out on which of the two markets will certainly become a lasting resource of long-term growth. The details of the respective country plan reform programs will establish which, if either, of the 2 fields prevails.

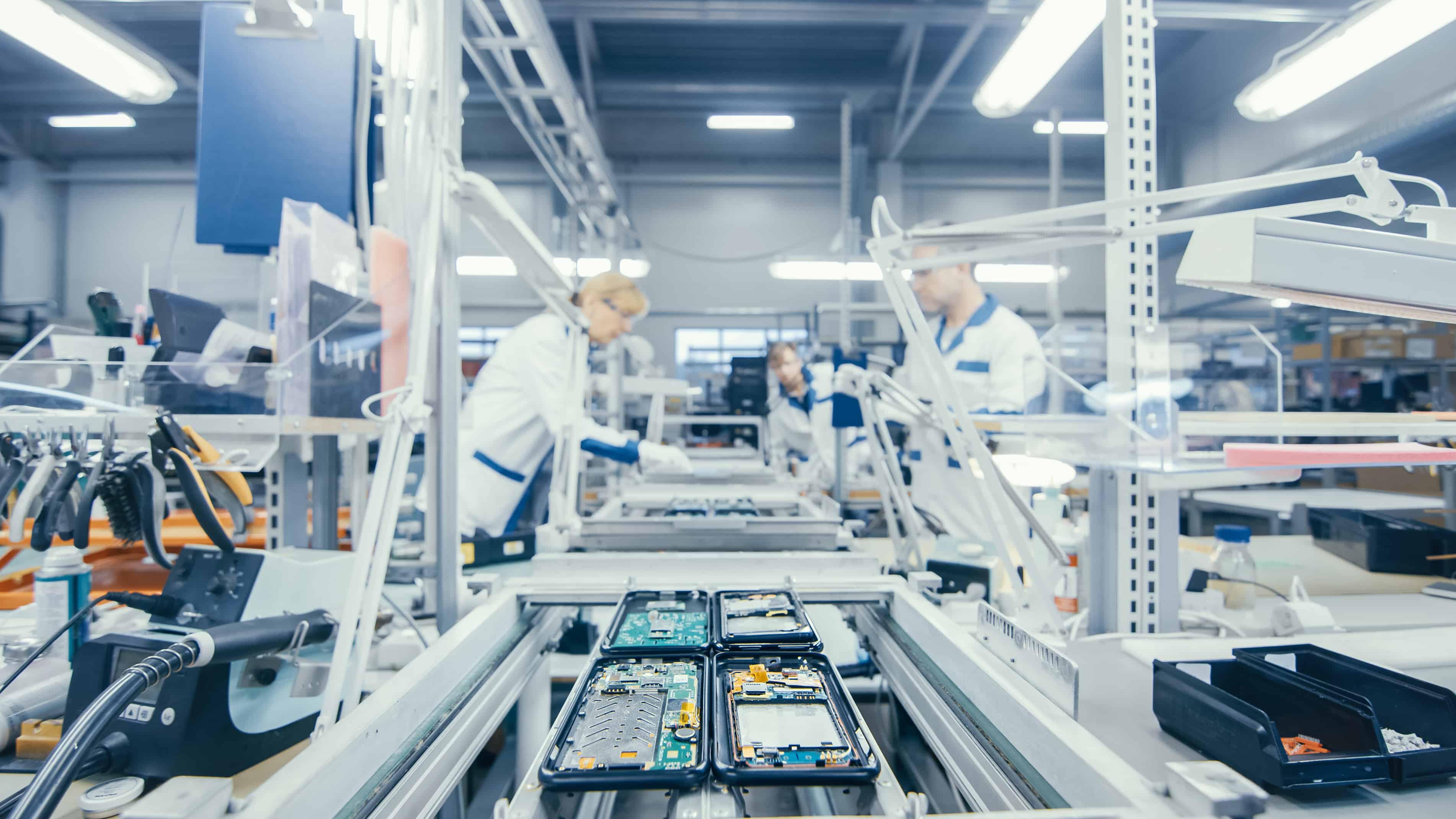

Some EMS firms even offer full worldwide find this supply chain administration and also advanced top quality systems, which might be a lot more innovative than those of the OEM. "The largest fad we see is the need for EMS firms to be a valued service partner, in addition to a manufacturing partner," said Rick Mc, Clain, president of Milwaukee Electronic devices, a Glendale, Wis.-based supplier of circuit card design and also printed circuit board (PCB) assembly.

The smart Trick of Bulk Materials Handling That Nobody is Discussing

"In action, contract makers are becoming extra incorporated with manufacturing growth, leveraging the most up to date modern technologies and also ability sets." One method to maintain costs down is Check This Out by transforming existing items into clever connected tools. "There is a large need for Io, T options on gadgets that are already on the marketplace, yet have yet to be electronically linked," stated Walt Maclay, head of state of Voler Solutions, a Sunnyvale, Calif.-based contract engineering company that focuses on the design of wearable and Io, T devices.

Along these lines, more business are buying systems modern technologies that sustain real-time information collection and also analysis while likewise boosting interactions with consumers on concerns connected to material availability and product lifecycle planning. New developments in Io, T, machine-to-machine communications, as well as the cloud (all of which depend upon electronics and sensing units) have emerged that are helping solve complicated manufacturing problems.

Some Known Factual Statements About Bulk Materials Handling

According to Susan Mucha, head of state of Powell-Mucha Consulting, an El Paso, Texas-based consulting company that functions with EMS service providers, the greatest setting up obstacle is material constraints. "Systems connection within the factory seems to be boosting, however when you have a supply chain where confirmed orders can be terminated the day they are arranged to ship, the very best systems in the globe don't transform that," she claimed."If electronics can remain to enhance towards those timelines, we can confirm our final products much faster as well as get to market sooner - bulk materials handling." Among one her response of the most current advances in 3D printing was accomplished by the College of Washington (UW) in partnership with SIJ Technology and also Japan's National Institute of Advanced Industrial Science and Innovation.

Report this wiki page